Cobalt-chrome: Difference between revisions

CSV import Tags: mobile edit mobile web edit |

CSV import |

||

| Line 35: | Line 35: | ||

[[Category:Biomedical engineering]] | [[Category:Biomedical engineering]] | ||

{{materials-science-stub}} | {{materials-science-stub}} | ||

<gallery> | |||

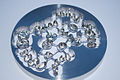

File:Disc_with_dental_implants_made_with_WorkNC.jpg|Disc with dental implants made with WorkNC | |||

File:Denture_example_2.jpg|Denture example | |||

</gallery> | |||

Latest revision as of 01:33, 18 February 2025

Cobalt-chrome or cobalt-chromium (CoCr) is a metal alloy of cobalt and chromium. It is highly valued for its wear resistance and ability to withstand extreme temperatures, making it an ideal material for various applications, including aerospace, dental, and medical implants. Cobalt-chrome has a very high specific strength and is corrosion-resistant, which makes it suitable for use in harsh environments.

Properties[edit]

Cobalt-chrome alloys are known for their exceptional strength and hardness, which are significantly higher than those of stainless steel or titanium alloys. This material also maintains its strength at high temperatures and exhibits a high degree of corrosion resistance, especially against salt water, chlorine, and some acids. Its biocompatibility makes it a preferred choice for medical implants.

Applications[edit]

Aerospace[edit]

In the aerospace industry, cobalt-chrome is used to manufacture aircraft engine parts due to its ability to retain strength at high temperatures and resist oxidation and wear.

Medical Implants[edit]

Cobalt-chrome is widely used in the medical field for manufacturing joint replacement implants, including hip, knee, and dental implants. Its high wear resistance and biocompatibility make it an ideal material for these applications.

Dentistry[edit]

In dentistry, cobalt-chrome is used for making dental prostheses and dental crowns. It is chosen for its durability, resistance to corrosion, and minimal allergic reactions compared to other materials.

Manufacturing Processes[edit]

Cobalt-chrome can be processed through various manufacturing techniques, including casting, forging, and additive manufacturing (3D printing). Additive manufacturing, in particular, has become increasingly popular for producing complex cobalt-chrome parts with high precision.

Advantages[edit]

- High wear resistance

- Excellent high-temperature strength

- Good corrosion resistance

- Biocompatibility

Disadvantages[edit]

- Higher cost compared to some other metals

- Difficult to machine due to its hardness

- Potential for cobalt ion release in medical implants, which could lead to health issues

Environmental and Health Concerns[edit]

While cobalt-chrome is beneficial in many applications, there are environmental and health concerns associated with cobalt mining and the potential release of cobalt ions from implants into the body. These issues are the subject of ongoing research and regulation.

This article is a Materials science-related stub. You can help WikiMD by expanding it!

-

Disc with dental implants made with WorkNC

-

Denture example