Trickling filter: Difference between revisions

CSV import |

CSV import |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Trickling Filter == | |||

A '''trickling filter''' is a type of [[wastewater treatment]] system that uses a bed of media to remove organic matter from [[sewage]]. The media, often made of rocks, gravel, or specially designed plastic shapes, provides a surface for [[microorganisms]] to grow and form a biofilm. As wastewater is distributed over the media, the microorganisms break down the organic pollutants. | |||

A trickling filter | |||

[[File:Benfleet_Sewage_Treatment_Plant,_Filter_Bed_-_geograph.org.uk_-_1450096.jpg|thumb|A trickling filter at Benfleet Sewage Treatment Plant]] | |||

== History == | |||

The concept of trickling filters dates back to the late 19th century. They were first developed in [[England]] and [[Germany]] as a method to treat sewage by allowing it to trickle over a bed of stones. The process was found to be effective in reducing [[biochemical oxygen demand]] (BOD) and [[suspended solids]] in wastewater. | |||

The trickling | |||

== | == Design and Operation == | ||

Trickling filters consist of a bed of media over which wastewater is distributed. The media can be made of various materials, including rocks, gravel, or plastic. The choice of media affects the efficiency and cost of the system. | |||

[[File:Trickle_Filter.svg|thumb|Diagram of a trickling filter system]] | |||

== | Wastewater is distributed over the media using a rotating arm or fixed nozzles. As the water trickles down, it comes into contact with the biofilm on the media. The microorganisms in the biofilm consume the organic matter, converting it into carbon dioxide, water, and biomass. | ||

* [[ | |||

* [[ | == Advantages and Disadvantages == | ||

Trickling filters are known for their simplicity and low operational costs. They do not require complex machinery and can operate with minimal energy input. However, they can be less effective in cold climates and may require large land areas. | |||

== Applications == | |||

Trickling filters are used in various settings, from small [[municipal wastewater treatment]] plants to large industrial facilities. They are particularly useful in areas where land is available and energy costs are a concern. | |||

[[File:Trickle_Filter_Cross-section.png|thumb|Cross-section of a trickling filter]] | |||

== Maintenance == | |||

Regular maintenance of trickling filters involves cleaning the distribution system and monitoring the growth of the biofilm. Excessive growth can lead to clogging, while insufficient growth can reduce treatment efficiency. | |||

== Related Pages == | |||

* [[Wastewater treatment]] | |||

* [[Biological treatment processes]] | |||

* [[Sewage treatment]] | * [[Sewage treatment]] | ||

[[ | == References == | ||

[[Category: | |||

* Metcalf & Eddy, Inc. (2003). ''Wastewater Engineering: Treatment and Reuse''. McGraw-Hill. | |||

* Tchobanoglous, G., Burton, F. L., & Stensel, H. D. (2003). ''Wastewater Engineering: Treatment and Reuse''. McGraw-Hill. | |||

[[File:Collapsed_trickling_filter_at_the_WWTP_in_Norton_(6845984347).jpg|thumb|Collapsed trickling filter at a wastewater treatment plant]] | |||

{{Commons category|Trickling filters}} | |||

[[Category:Wastewater treatment]] | |||

<gallery> | |||

File:Benfleet_Sewage_Treatment_Plant,_Filter_Bed_-_geograph.org.uk_-_1450096.jpg|Benfleet Sewage Treatment Plant Filter Bed | |||

File:Trickle_Filter.svg|Diagram of a Trickle Filter | |||

File:Trickle_Filter_Cross-section.png|Cross-section of a Trickle Filter | |||

File:Collapsed_trickling_filter_at_the_WWTP_in_Norton_(6845984347).jpg|Collapsed Trickling Filter at the WWTP in Norton | |||

</gallery> | |||

Latest revision as of 04:32, 18 February 2025

Trickling Filter[edit]

A trickling filter is a type of wastewater treatment system that uses a bed of media to remove organic matter from sewage. The media, often made of rocks, gravel, or specially designed plastic shapes, provides a surface for microorganisms to grow and form a biofilm. As wastewater is distributed over the media, the microorganisms break down the organic pollutants.

History[edit]

The concept of trickling filters dates back to the late 19th century. They were first developed in England and Germany as a method to treat sewage by allowing it to trickle over a bed of stones. The process was found to be effective in reducing biochemical oxygen demand (BOD) and suspended solids in wastewater.

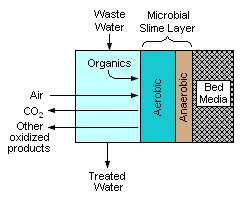

Design and Operation[edit]

Trickling filters consist of a bed of media over which wastewater is distributed. The media can be made of various materials, including rocks, gravel, or plastic. The choice of media affects the efficiency and cost of the system.

Wastewater is distributed over the media using a rotating arm or fixed nozzles. As the water trickles down, it comes into contact with the biofilm on the media. The microorganisms in the biofilm consume the organic matter, converting it into carbon dioxide, water, and biomass.

Advantages and Disadvantages[edit]

Trickling filters are known for their simplicity and low operational costs. They do not require complex machinery and can operate with minimal energy input. However, they can be less effective in cold climates and may require large land areas.

Applications[edit]

Trickling filters are used in various settings, from small municipal wastewater treatment plants to large industrial facilities. They are particularly useful in areas where land is available and energy costs are a concern.

Maintenance[edit]

Regular maintenance of trickling filters involves cleaning the distribution system and monitoring the growth of the biofilm. Excessive growth can lead to clogging, while insufficient growth can reduce treatment efficiency.

Related Pages[edit]

References[edit]

- Metcalf & Eddy, Inc. (2003). Wastewater Engineering: Treatment and Reuse. McGraw-Hill.

- Tchobanoglous, G., Burton, F. L., & Stensel, H. D. (2003). Wastewater Engineering: Treatment and Reuse. McGraw-Hill.

-

Benfleet Sewage Treatment Plant Filter Bed

-

Diagram of a Trickle Filter

-

Cross-section of a Trickle Filter

-

Collapsed Trickling Filter at the WWTP in Norton