Cyclic olefin copolymer: Difference between revisions

CSV import |

CSV import |

||

| Line 36: | Line 36: | ||

[[Category:Materials science]] | [[Category:Materials science]] | ||

{{Chemistry-stub}} | {{Chemistry-stub}} | ||

== Cyclic olefin copolymer gallery == | |||

<gallery> | |||

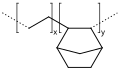

File:Cyclic olefin copolymer.svg|Cyclic olefin copolymer | |||

</gallery> | |||

Latest revision as of 05:54, 3 March 2025

Cyclic Olefin Copolymer (COC) is a type of polymer that is gaining attention in various industries due to its unique properties. COC is produced through the copolymerization of ethylene and norbornene or other cyclic olefins. This material combines the advantageous characteristics of both components, resulting in a polymer with excellent transparency, low moisture absorption, high heat resistance, and good barrier properties against gases. These features make COC a valuable material in the medical, optical, and packaging sectors.

Properties[edit]

COC exhibits several notable properties that distinguish it from other polymers:

- High Transparency: COC has a high refractive index and low birefringence, making it ideal for optical applications.

- Heat Resistance: It can withstand temperatures significantly higher than many other plastics, making it suitable for applications requiring sterilization.

- Chemical Resistance: COC is resistant to acids, bases, and many organic solvents.

- Low Moisture Absorption: Its low water absorption rate ensures that it maintains its properties in humid environments.

- Barrier Properties: COC has excellent barrier properties against gases like oxygen and carbon dioxide, which is crucial for packaging applications.

Applications[edit]

Due to its unique properties, COC is used in a variety of applications:

- Medical Devices: Its biocompatibility and sterilizability make it suitable for syringes, vials, and other medical containers.

- Optical Lenses: The high transparency and low birefringence of COC are ideal for optical lenses and components.

- Packaging: Its excellent barrier properties and chemical resistance make it a good choice for food, cosmetic, and pharmaceutical packaging.

- Electronics: COC's properties are beneficial for electronic packaging, including LCD panels and LED molds.

Production[edit]

The production of COC involves the copolymerization of ethylene with cyclic olefins, such as norbornene. This process typically uses metallocene catalysts, which allow for precise control over the polymer structure, resulting in materials with specific properties tailored to their intended applications.

Environmental Impact[edit]

COC is considered to be more environmentally friendly compared to some other polymers. It is recyclable and can be incinerated cleanly, producing water and carbon dioxide without releasing harmful substances.

Challenges and Future Directions[edit]

While COC offers many advantages, there are challenges to its wider adoption, including its relatively high cost compared to some conventional polymers. Ongoing research focuses on developing more cost-effective production methods and expanding the range of applications for COC.

See Also[edit]

- Polymer

- Copolymerization

- Biocompatibility

- Sterilization (microbiology)

- Refractive index

- Birefringence

Cyclic olefin copolymer gallery[edit]

-

Cyclic olefin copolymer