Hot runner: Difference between revisions

CSV import |

CSV import |

||

| Line 29: | Line 29: | ||

[[Category:Plastics industry]] | [[Category:Plastics industry]] | ||

{{manufacturing-stub}} | {{manufacturing-stub}} | ||

<gallery> | |||

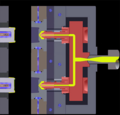

File:Hot_runner_x-section_open.png|Hot runner cross-section open | |||

File:Hot_runner_x-section_injection.png|Hot runner cross-section injection | |||

File:Mold_x-section3_orycon.png|Mold cross-section | |||

</gallery> | |||

Latest revision as of 02:17, 18 February 2025

Hot runner systems are a critical component in the field of plastic injection molding, designed to convey molten plastic from the machine's nozzle into the cavities of the injection mold. Unlike cold runner systems, where the runner (the channel through which the plastic flows) cools and solidifies with the part, hot runners keep the plastic molten throughout the cycle. This technology significantly improves the efficiency of the molding process by reducing waste, cycle time, and improving part quality.

Overview[edit]

Hot runner systems consist of two main components: the manifold and the nozzles. The manifold is responsible for distributing the plastic to various points within the mold, while the nozzles direct the flow of plastic into the mold cavities. These systems can be internally heated to ensure the plastic remains in a molten state, facilitating a more efficient flow and reducing the risk of defects in the final product.

Types of Hot Runner Systems[edit]

There are generally two types of hot runner systems: externally heated and internally heated. Externally heated systems heat the plastic from the outside, preventing any contact between the heating elements and the plastic. This is particularly useful for materials sensitive to thermal degradation. Internally heated systems, on the other hand, use heating elements placed inside the runner channels to ensure the plastic remains molten.

Advantages[edit]

The use of hot runner systems offers several advantages over traditional cold runner systems:

- Reduced Waste: Since the runner system is heated, the plastic within it never solidifies, eliminating the waste associated with the cold runner.

- Faster Cycle Times: The elimination of the solidification time for the runner allows for faster cycle times.

- Improved Quality: The consistent temperature control reduces the risk of defects related to material viscosity.

- Material Savings: By eliminating the runner, material usage is significantly reduced, leading to cost savings.

Disadvantages[edit]

Despite their advantages, hot runner systems also have some drawbacks:

- Higher Initial Cost: The complexity and technology of hot runner systems make them more expensive to purchase and install.

- Maintenance: They require more maintenance and cleaning to prevent issues such as clogging or leakage.

- Thermal Degradation: There is a higher risk of thermal degradation of the plastic if the temperature is not properly controlled.

Applications[edit]

Hot runner systems are used in various applications where efficiency, part quality, and waste reduction are critical. They are particularly beneficial in the automotive, medical, and consumer electronics industries, where precision and reliability are paramount.

Conclusion[edit]

Hot runner systems have revolutionized the plastic injection molding industry by improving efficiency, reducing waste, and enhancing the quality of the final product. Despite their higher initial cost and maintenance requirements, the benefits they offer make them an indispensable tool in modern manufacturing processes.

-

Hot runner cross-section open

-

Hot runner cross-section injection

-

Mold cross-section