Computer-aided manufacturing: Difference between revisions

CSV import Tags: mobile edit mobile web edit |

CSV import |

||

| Line 33: | Line 33: | ||

[[Category:Manufacturing software]] | [[Category:Manufacturing software]] | ||

[[Category:Technology]] | [[Category:Technology]] | ||

<gallery> | |||

File:CAD_model_and_CNC_machined_part.PNG|CAD model and CNC machined part | |||

File:Disc_with_dental_implants_made_with_WorkNC.jpg|Disc with dental implants made with WorkNC | |||

</gallery> | |||

Latest revision as of 02:13, 18 February 2025

Computer-aided manufacturing (CAM) is a technology that utilizes computer software and hardware to automate and control the manufacturing process. It plays a crucial role in modern manufacturing industries by improving efficiency, accuracy, and productivity. CAM systems integrate with computer-aided design (CAD) software to generate instructions for automated machinery, such as CNC (computer numerical control) machines, robots, and 3D printers.

History[edit]

The origins of computer-aided manufacturing can be traced back to the 1950s when early numerical control (NC) machines were developed. These machines used punched cards to control the movement of cutting tools. Over the years, advancements in computer technology led to the development of more sophisticated CAM systems. In the 1970s, the introduction of computer-aided design and manufacturing (CAD/CAM) systems revolutionized the manufacturing industry by enabling designers and engineers to create and manufacture products more efficiently.

Functionality[edit]

CAM software provides a wide range of functionality to streamline the manufacturing process. It allows users to create and modify digital models of parts or products using CAD software. These digital models are then used to generate toolpaths, which are instructions that guide the movement of cutting tools or other manufacturing equipment. CAM systems also optimize toolpaths to minimize production time and reduce material waste. Additionally, CAM software can simulate and analyze the manufacturing process to identify potential issues and optimize production parameters.

Benefits[edit]

Computer-aided manufacturing offers several benefits to manufacturers. Firstly, it improves accuracy and precision by eliminating human errors and inconsistencies. CAM systems can perform complex calculations and generate precise toolpaths, resulting in higher quality products. Secondly, CAM software increases productivity by automating repetitive tasks and reducing setup time. This allows manufacturers to produce more goods in less time, leading to higher output and profitability. Lastly, CAM systems enable manufacturers to quickly adapt to design changes or customizations, as the digital models can be easily modified and the toolpaths regenerated.

Applications[edit]

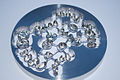

Computer-aided manufacturing is widely used in various industries, including automotive, aerospace, electronics, and medical device manufacturing. In the automotive industry, CAM systems are used to produce complex components with high precision, such as engine parts and body panels. In aerospace, CAM software is utilized to manufacture aircraft components, including turbine blades and structural parts. The electronics industry relies on CAM systems to produce printed circuit boards (PCBs) and electronic components. In the medical device field, CAM technology is used to manufacture implants, prosthetics, and surgical instruments.

Future Developments[edit]

The future of computer-aided manufacturing is promising, with several emerging technologies and trends. One such trend is the integration of CAM with additive manufacturing, also known as 3D printing. This combination allows for the production of complex geometries and customized products with minimal material waste. Another development is the use of artificial intelligence (AI) and machine learning algorithms in CAM systems. These technologies can optimize toolpaths, predict and prevent manufacturing errors, and improve overall efficiency. Additionally, the adoption of cloud-based CAM software enables real-time collaboration and remote access to manufacturing data, enhancing flexibility and scalability.

See Also[edit]

- Computer-aided design

- Numerical control

- Additive manufacturing

- Artificial intelligence in manufacturing

References[edit]

<references />

-

CAD model and CNC machined part

-

Disc with dental implants made with WorkNC