Molecular sieve: Difference between revisions

CSV import Tags: mobile edit mobile web edit |

CSV import |

||

| Line 53: | Line 53: | ||

{{DEFAULTSORT:Molecular Sieve}} | {{DEFAULTSORT:Molecular Sieve}} | ||

{{Chemistry-stub}} | {{Chemistry-stub}} | ||

== Molecular sieve gallery == | |||

<gallery> | |||

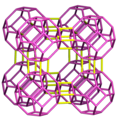

File:LTA (cropped).png|LTA (cropped) | |||

File:MSN vials.JPG|MSN vials | |||

File:4A sieves.JPG|4A sieves | |||

</gallery> | |||

Latest revision as of 05:55, 3 March 2025

Molecular sieve is a material with pores (very small holes) of uniform size. These pores are small enough to block large molecules and allow smaller molecules to pass through, making molecular sieves useful for separating and purifying gases and liquids. They are often used in the chemical, petrochemical, and natural gas industries, among others, to remove water or other impurities from process streams.

Types of Molecular Sieves[edit]

Molecular sieves are classified by their pore size, typically measured in angstroms (Å), and can be made from various materials, including zeolites, carbon, silica gel, and others. The most common types include:

- 3A: With a pore size of 3 Å, it is used primarily for drying, removing water from gases and liquids.

- 4A: With a pore size of 4 Å, it can remove water, but also gases like CO2, SO2, and H2S from streams.

- 5A: With a pore size of 5 Å, it is used for separating hydrocarbons, purifying gas streams, and in air separation.

- 13X: With a pore size of approximately 10 Å, it is used for general gas drying, air separation, and the removal of CO2 and H2S.

Applications[edit]

Molecular sieves have a wide range of applications due to their ability to selectively adsorb molecules based on size. Some common applications include:

- Gas and Liquid Drying: Removing water from natural gas, air, and refrigerants.

- Air Separation: Separating oxygen, nitrogen, and other gases from air.

- Purification: Removing impurities like CO2, SO2, H2S, and mercaptans from gas streams.

- Catalysis: Acting as catalysts in various chemical reactions due to their unique pore structures.

Advantages[edit]

Molecular sieves offer several advantages over other drying and purification methods:

- High Selectivity: Their uniform pore sizes allow for the selective adsorption of molecules.

- High Capacity: They can adsorb a large amount of material relative to their weight.

- Regenerability: Molecular sieves can be regenerated (dried or cleaned) and reused multiple times by heating or reducing pressure.

Regeneration[edit]

Regeneration of molecular sieves involves removing the adsorbed substances from the sieve's pores. This is typically done by either increasing the temperature (thermal swing adsorption) or reducing the pressure (pressure swing adsorption) to desorb the adsorbed material.

Safety and Handling[edit]

While molecular sieves are generally safe to handle, they can cause skin dryness or irritation due to their high adsorption capacity. Proper personal protective equipment (PPE) should be used when handling them.

Environmental Impact[edit]

Molecular sieves are considered environmentally friendly due to their regenerability and efficiency in purifying and separating gases and liquids without the use of harmful chemicals.

See Also[edit]

References[edit]

<references/>

External Links[edit]

Molecular sieve gallery[edit]

-

LTA (cropped)

-

MSN vials

-

4A sieves