Acheson process: Difference between revisions

CSV import |

CSV import |

||

| Line 41: | Line 41: | ||

[[Category:Silicon compounds]] | [[Category:Silicon compounds]] | ||

[[Category:Graphite]] | [[Category:Graphite]] | ||

<gallery> | |||

File:Acheson_furnace.svg|Acheson furnace | |||

File:Resistive_Acheson_Furnace.svg|Resistive Acheson Furnace | |||

File:Castner_lengthwise_graphitization_furnace.svg|Castner lengthwise graphitization furnace | |||

</gallery> | |||

Latest revision as of 03:53, 18 February 2025

A process for producing synthetic graphite and silicon carbide

The Acheson process is an industrial method for producing silicon carbide and synthetic graphite. It was invented by Edward Goodrich Acheson in 1891. The process involves heating a mixture of silica or silicon dioxide and carbon in an electric furnace, known as the Acheson furnace.

History[edit]

The Acheson process was developed in the late 19th century by Edward Goodrich Acheson, who was experimenting with ways to produce artificial diamonds. During his experiments, he discovered that heating a mixture of clay and carbon resulted in the formation of silicon carbide, which he named "carborundum." This discovery led to the development of the Acheson process for the commercial production of silicon carbide.

Process[edit]

The Acheson process involves the following steps:

- A mixture of silica (SiO_) and carbon (usually in the form of coke) is prepared.

- The mixture is placed in an Acheson furnace, which is a type of resistive heating furnace.

- An electric current is passed through the furnace, generating high temperatures (up to 2500°C) that cause the silica and carbon to react, forming silicon carbide (SiC) and carbon monoxide (CO).

- The silicon carbide is then cooled and collected for further processing or use.

Applications[edit]

Silicon carbide produced by the Acheson process is used in a variety of applications, including:

- As an abrasive material in grinding and cutting tools.

- In the production of refractory materials due to its high thermal conductivity and resistance to thermal shock.

- As a semiconductor material in high-temperature and high-voltage electronic devices.

Acheson Furnace[edit]

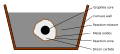

The Acheson furnace is a key component of the Acheson process. It is a type of resistive heating furnace that uses graphite electrodes to conduct electricity and generate the high temperatures needed for the reaction. The furnace is designed to withstand the extreme conditions of the process and is typically lined with refractory materials to protect it from the corrosive effects of the reaction.

Related pages[edit]

Gallery[edit]

-

Diagram of an Acheson furnace

-

Resistive Acheson furnace

-

Castner lengthwise graphitization furnace

-

Acheson furnace

-

Resistive Acheson Furnace

-

Castner lengthwise graphitization furnace