Microfiltration: Difference between revisions

CSV import |

CSV import |

||

| Line 33: | Line 33: | ||

{{Template:Technology-stub}} | {{Template:Technology-stub}} | ||

== Microfiltration gallery == | |||

<gallery> | |||

File:Overall setup for the Microfiltration system - PNG.png|Overall setup for the Microfiltration system | |||

File:Cross-flow.svg|Cross-flow | |||

File:Dead-end.svg|Dead-end | |||

File:Cutaway of a microfiltration module with hollow fiber membranes at a NEWater plant.jpg|Cutaway of a microfiltration module with hollow fiber membranes at a NEWater plant | |||

</gallery> | |||

Latest revision as of 06:10, 3 March 2025

Microfiltration is a process in the field of filtration that involves the physical separation of solids from fluids (liquids or gases) by passing the fluid through a microporous membrane. The size of the pores in the membrane determines the extent to which suspended particles, microorganisms, and other substances can be removed. Typically, microfiltration membranes have pore sizes ranging from 0.1 to 10 micrometers (µm). This technology is widely used in various industries, including water treatment, food and beverage processing, pharmaceuticals, and biotechnology, for applications such as sterilization, clarification, and cell harvesting.

Principles of Microfiltration[edit]

Microfiltration operates on the principle of physical size exclusion. Particles larger than the membrane pores are retained on the membrane surface or within the pores, while the fluid and smaller particles pass through as the permeate. The process can be driven by gravity, pressure, or vacuum, with pressure-driven processes being the most common. The effectiveness of microfiltration is influenced by factors such as membrane material, pore size, operating pressure, and flow rate.

Applications[edit]

Water Treatment[edit]

In water treatment, microfiltration is used to remove suspended solids, bacteria, protozoa, and some viruses from water, making it an essential step in the production of potable water. It is also employed in wastewater treatment to reduce turbidity and for the recovery of valuable materials.

Food and Beverage Processing[edit]

Microfiltration is applied in the food and beverage industry to clarify beverages, such as wine and beer, by removing yeast and other particulates. It is also used in the dairy industry for the removal of bacteria from milk and the concentration and fractionation of proteins.

Pharmaceuticals[edit]

In the pharmaceutical industry, microfiltration is utilized for the sterile filtration of drugs, vaccines, and other therapeutic products. It ensures the removal of microorganisms and particulate matter, meeting regulatory requirements for product safety.

Biotechnology[edit]

Microfiltration plays a crucial role in biotechnology for the separation and purification of biomolecules, cell harvesting, and media preparation in bioprocesses.

Membrane Materials[edit]

Microfiltration membranes can be made from a variety of materials, including polymers (e.g., polyethersulfone, polyvinylidene fluoride) and ceramics. The choice of material depends on the application, considering factors such as chemical compatibility, thermal stability, and mechanical strength.

Advantages and Limitations[edit]

Microfiltration offers several advantages, including low energy consumption, the ability to operate at ambient temperatures, and the preservation of the biological and chemical integrity of the permeate. However, membrane fouling, which can reduce efficiency and increase operational costs, is a significant limitation. Regular cleaning and maintenance are required to mitigate fouling and prolong membrane life.

Future Directions[edit]

Research in microfiltration technology focuses on developing advanced membranes with higher selectivity, reduced fouling, and improved durability. Innovations in membrane materials and configurations aim to enhance performance and expand the range of applications.

Microfiltration gallery[edit]

-

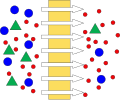

Overall setup for the Microfiltration system

-

Cross-flow

-

Dead-end

-

Cutaway of a microfiltration module with hollow fiber membranes at a NEWater plant