Polychlorotrifluoroethylene: Difference between revisions

CSV import |

CSV import |

||

| Line 24: | Line 24: | ||

{{chemistry-stub}} | {{chemistry-stub}} | ||

{{material-stub}} | {{material-stub}} | ||

== Polychlorotrifluoroethylene == | |||

<gallery> | |||

File:Polychlorotrifluoroethylene.svg | |||

</gallery> | |||

Latest revision as of 21:58, 16 February 2025

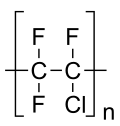

Polychlorotrifluoroethylene (PCTFE) is a high-performance plastic material, known for its unique properties. It is a type of fluoropolymer that is produced by the polymerization of chlorotrifluoroethylene.

Properties[edit]

Polychlorotrifluoroethylene is characterized by its excellent chemical resistance, high mechanical strength, and low gas permeability. It is non-flammable and has a wide temperature range for use, from -400°F to 400°F (-240°C to 204°C). It also has excellent electrical properties, making it suitable for use in a variety of applications.

Applications[edit]

Due to its unique properties, PCTFE is used in a wide range of industries. In the pharmaceutical industry, it is used for packaging materials due to its low moisture absorption and excellent barrier properties. In the aerospace industry, it is used for seals, gaskets, and other components due to its low outgassing properties. It is also used in the chemical industry for lining tanks and pipes due to its excellent chemical resistance.

Production[edit]

The production of PCTFE involves the polymerization of chlorotrifluoroethylene. This is typically done using a free radical initiator in a high-pressure reactor. The resulting polymer is then processed into the desired form, such as sheets, rods, or films.

Health and Safety[edit]

As with all fluoropolymers, care should be taken when handling PCTFE. While it is generally considered safe, it can produce harmful fumes if heated to decomposition. Therefore, it should always be used in a well-ventilated area and appropriate personal protective equipment should be worn.

See Also[edit]